This article explores the benefits of automatic center board cutters like the HX390A in bookbinding, emphasizing increased efficiency, accuracy, and reduced waste.

|

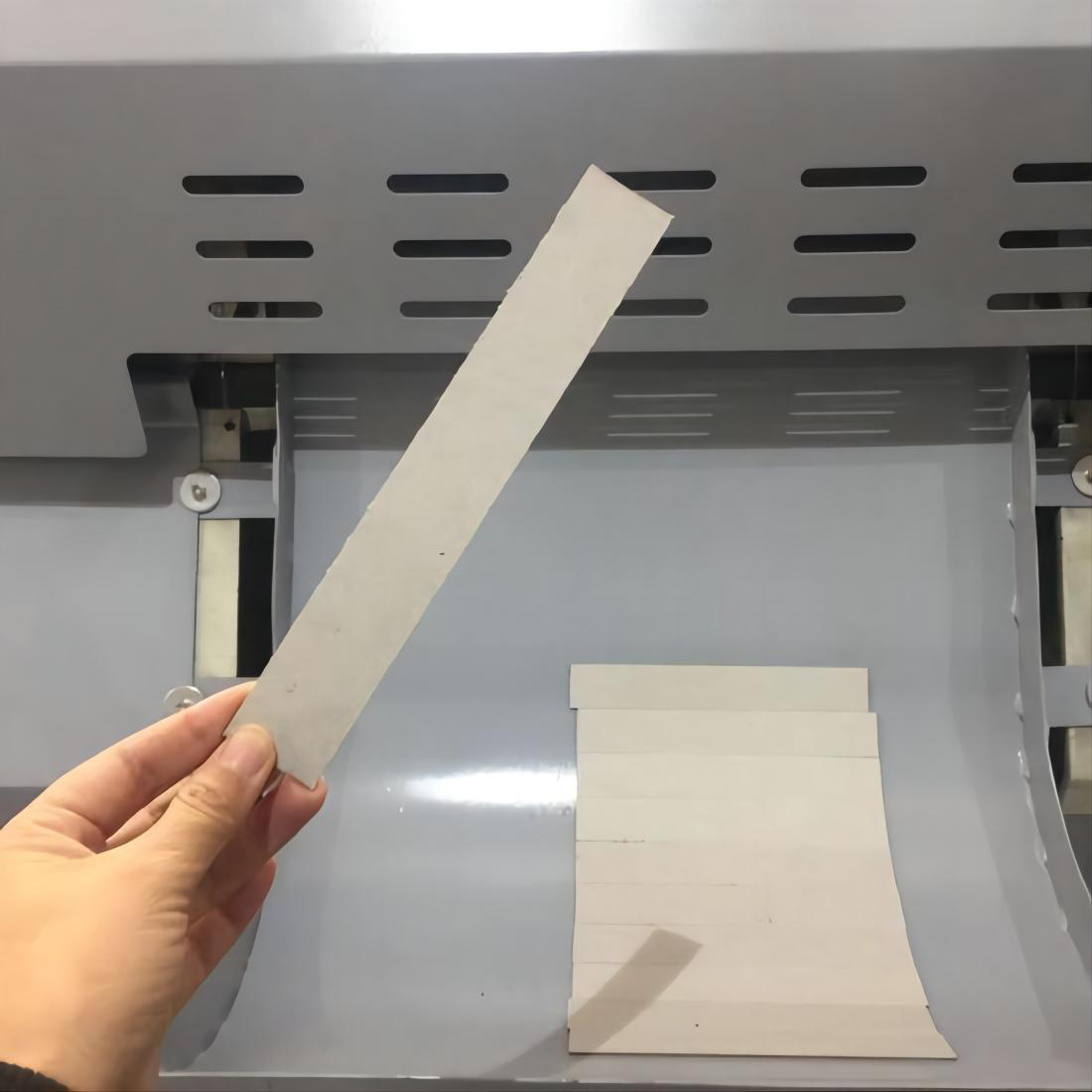

The bookbinding industry is constantly evolving, with demands for efficiency and precision increasing daily. One crucial aspect of producing high-quality books, especially layflat books, is the precise cutting of center boards. Traditionally, this process has been time-consuming and prone to errors. However, the introduction of automatic center board cutters like the HX390A is transforming the landscape, allowing for faster, more accurate production. These machines are not just about speed; they are about maintaining consistent quality and reducing waste. The use of such advanced technology represents a significant leap forward in book manufacturing. The key advantage of an automatic center board cutter is its ability to automate what was previously a labor-intensive task. With features like auto-feeding mechanisms and programmable cutting parameters, these machines minimize manual intervention, allowing operators to focus on other aspects of the production process. This automation results in reduced labor costs and increased production output. For businesses striving to meet tight deadlines and maintain high-quality standards, automation through tools like the HX390A is not just a luxury; it's a necessity.  The HX390A is a prime example of this technological advancement. Its intelligent design and advanced cutting capabilities make it an ideal choice for businesses looking to improve their bookbinding processes. The machine’s ability to accurately cut center boards ensures that layflat books have a smooth, even finish. This consistency is crucial for customer satisfaction and reflects positively on the quality of the final product. Furthermore, its robust build ensures reliability and reduces the risk of costly downtime.  The impact of automatic center board cutters extends beyond simple efficiency gains. By reducing human error, these machines contribute to a more consistent product. This is particularly important in the production of high-value books where precision is paramount. The introduction of technology like the HX390A signals a commitment to quality and innovation within the bookbinding industry. It shows that automation is the path to achieving higher standards and increased productivity simultaneously.  In conclusion, the integration of automatic center board cutters like the HX390A represents a significant shift in the bookbinding process. Its ability to deliver speed, accuracy, and consistency makes it an invaluable asset for modern book manufacturers. By embracing this technology, businesses can position themselves for sustained growth and enhanced customer satisfaction. The future of bookbinding is undoubtedly intertwined with the continued development and adoption of such innovative solutions. |

| Tag:Automatic Center Board Cutter,Bookbinding Automation,Board Cutting Technology,hardcover case,case making machine |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!